Quartering 101

I have been working with some of you over the past several months on viewing your technicians on sampling and quartering procedures. I still have a bunch of folks to look at in the coming months ahead.

I have seen very few that follow the SC-T-72 procedure for quartering correctly. This is concerning due to the number of samples that are taken every day and your LPFs are directly affected by these steps that may affect 1000’s of tons of mix per day or way more tons under the current verification specification.

The response from most of the technicians when asked how are doing on split samples with SCDOT:

“We are not having any issues comparing to SCDOT”.

This can be defined as:

- You are consistent and good at sampling and testing.

- You are just lucky you have not got a non-comparison that has not been in your organization’s favor.

You should also be concerned with:

Are your QC/QA samples representative of the mix being produced?

This affects your daily LPF and your ability to trust the results and make accurate daily adjustments at the plant to target JMF.

Some of my early findings include:

Truck Sampling:

- Sample buckets should be clean – being sure not to contaminate your daily QC/QA samples from previous day’s material.

- Be sure you are obtaining enough mix off the truck, whether you use a round point or square shovel as stated in your QC plan, be sure and get large shovel full of material from the truck and dump carefully into your bucket or pails to avoid spillage.

- When volumetrics are required for the LOT; obtain two buckets, one for Volumetrics, and the other for your QC/QA tests and SCDOT Splits.

Quartering:

Don’t be in a hurry to rush through your samples, if you have extra pressure to get split samples to SCDOT and have them on their way to another plant, don’t cut corners. Take the time to quarter the samples as with your QC/QA tests. All samples should be considered pay samples, so be deliberant with your sampling and testing.

If you don’t have the time and willing to put the effort to quarter and box your samples for SCDOT, then bag your samples and let SCDOT quarter the samples. Discuss this within your own QC department and decide what is best for your organization.

#1 Re-occurring issue – Obtaining a scoop or trowel sample from the quartering table and walk to scale and shake off into a box or pan until the sample size if obtained. This is not following the SC-T-72 procedure, remember especially on coarser mixtures, larger particles will often roll off first or fall to the side.

Digging into the selected quarter to remove a couple hundred grams or going back to the quartering table and scooping out (not slicing off a portion) a few hundred more grams is not following the procedure. By doing this technique, how do you know you are removing or adding material that is representative of the asphalt mixture?

See the next page to help demonstrate the quartering methods. There is also a video (attached) that one of our members took the extra effort on developing several videos for training their technicians.

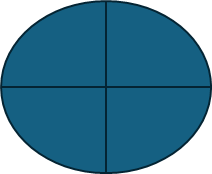

Dump the sample bucket of mix quickly in one drop onto the quartering table, pull mix together and spread out into circle approximately 2-3 inches in thickness, careful not to spill any mix. Divide into four equal quarters and clean trowel of fines.

Depending on size of sample, pull an individual quarter away to sample from or add opposing quarters to get desired sample size. Practice makes this much easier over time.

Spread the sampled smaller portion - quarter out once again, and divide again into 4 pieces…

Repeat and pull away opposite quarters to make room and assist you with being able to pull or collect sample from the quartering table.

Tech Tip: Find a several sample pans that hold the correct sample size range to prevent the need to walk back and forth to the scale.

Pull a one quarter and weigh on a scale to see if are close to the required sample size for the test.

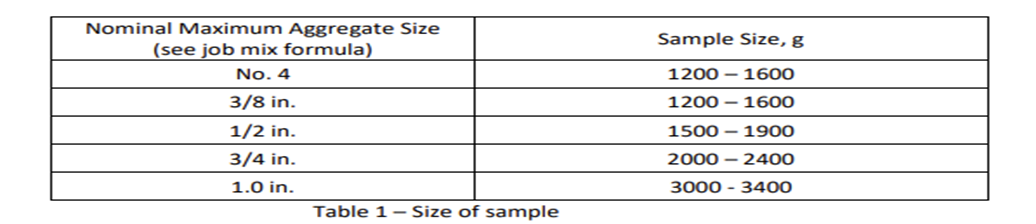

- IF the weight is too small: Keep entire quarter and go back to the table and quarter the remaining quarter and repeat process adding smaller portions of the quarter to your sample until the weight falls within the table tolerance in the table above. Remember to clean trowel after meeting sample size and take ¼ of the fines.

- IF the weight is too large: Do not dig into the sample to remove material, simply go back to the table and start the process over with an unused quarter. Again, reducing it by quartering and removing unwanted quarters until sample size is met. Remember to clean trowel after meeting sample size and take ¼ of the fines.

- Repeat process in the same way for all QC/QA test samples and sample boxes for SCDOT. If a bagged sample for SCDOT is used, place all undisturbed quartering into the bag, be sure the bagged sample size meets SC-T-62 to very have sufficient sample to repeat the quartering process. Remember to clean trowel after meeting sample size and take ¼ of the fines.